1. Introduction

Clinical laboratories are vital for diagnostics, disease monitoring, and research. The efficiency of their supply chains directly influences their operational quality and reliability. Ensuring a steady flow of reagents, consumables, and equipment is crucial for both routine functions and emergency preparedness.

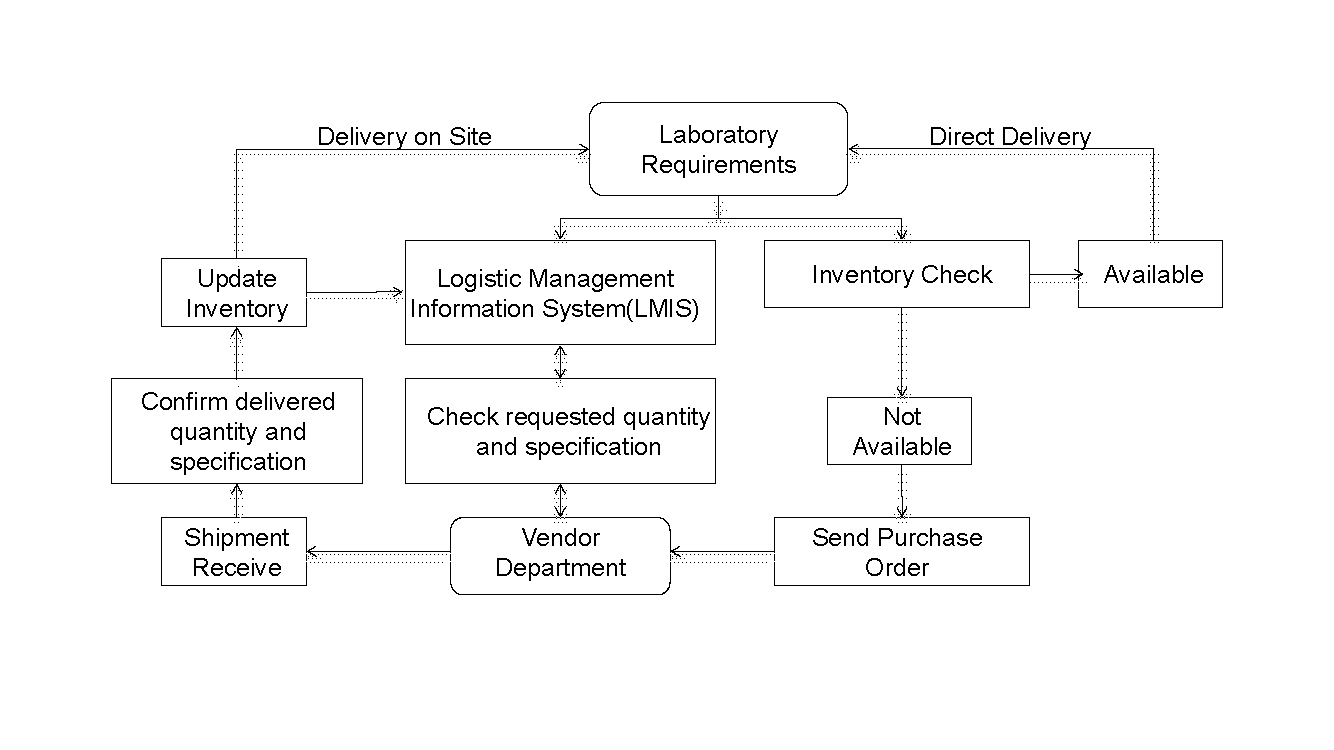

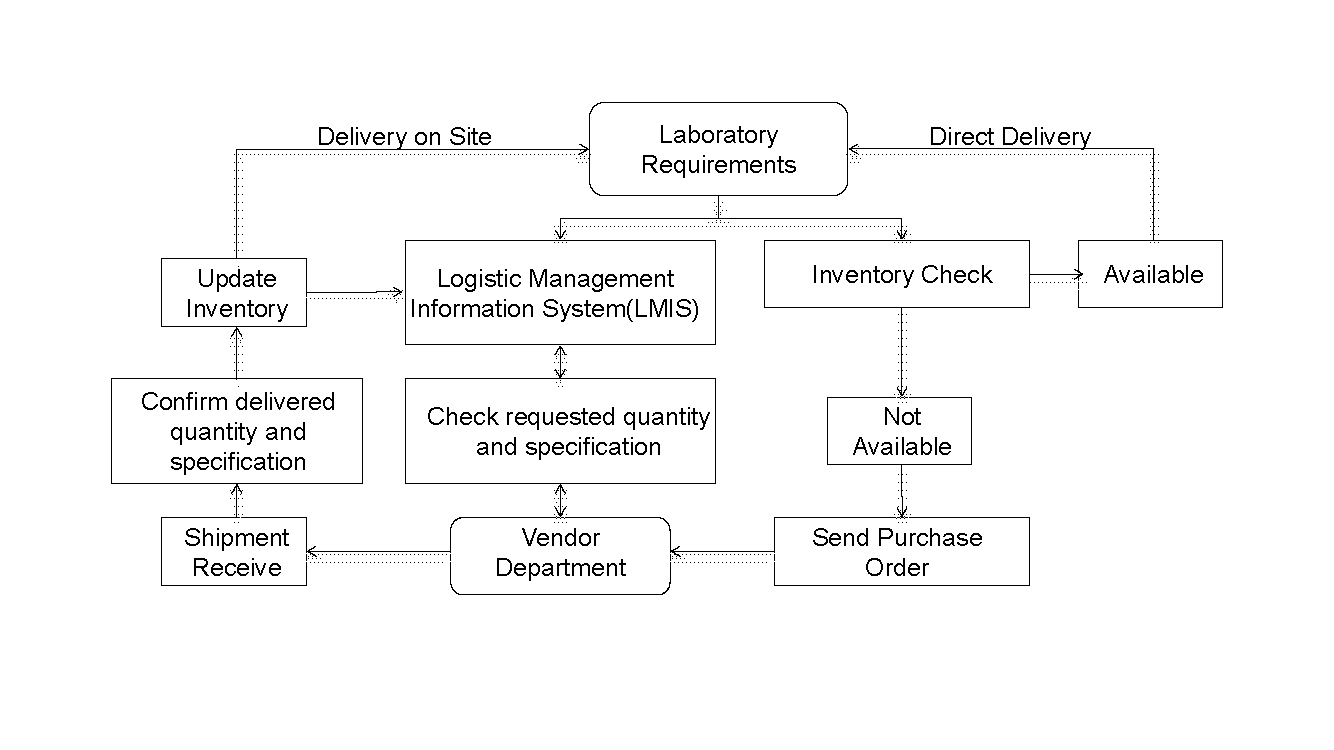

Fig. 1: Supply Chain Management in Laboratories [1]

2. The Importance of Optimized Laboratory Supply Chains

A well-managed laboratory supply chain is essential for preventing operational setbacks caused by material shortages, ensuring timely patient diagnoses and uninterrupted research activities. Delays in receiving critical supplies like reagents or equipment can severely impact the accuracy of tests, timely diagnoses, and overall laboratory productivity.[1] Supply chain optimization improves resource utilization by reducing waste through better inventory control and streamlining procurement processes. This not only minimizes operational costs but also maximizes cost-efficiency, allowing laboratories to operate within budget while meeting the demands of routine and emergency operations.[2] Moreover, a well-optimized supply chain gives laboratories a competitive edge by improving their responsiveness to market changes and the ability to scale research efforts quickly. In times of crisis, such as disease outbreaks or pandemics, optimized supply chains enable laboratories to act swiftly, maintaining support for healthcare systems and ensuring research continuity.[3]

3. Key Strategies for Reliable Supplies

3.1. Inventory Management

Advanced inventory tools like barcode scanners and RFID systems ensure real-time stock tracking, enhancing accuracy and minimizing delays. Automated alerts for low stock levels enable timely reordering, preventing disruptions.[1] Historical data analysis combined with predictive analytics helps forecast demand, accommodating seasonal spikes or unexpected disease outbreaks.[2] This approach is vital during health crises, as seen in recent pandemics.[3] Integrating machine learning can refine forecasting precision. Safety stock levels must be strategically set, balancing material criticality, procurement lead times, and supply reliability to avoid tying up resources unnecessarily.[1] Risk-based inventory strategies ensure preparedness for potential delays while maintaining cost efficiency.[2]

3.2. Supplier Management

Building a resilient supply chain starts with a thorough evaluation of suppliers. Key factors to consider include product quality, production capacity, and financial stability.[1] A supplier’s ability to meet production demands consistently and maintain high-quality standards is essential for smooth laboratory operations. Evaluating their financial health ensures that labs partner with suppliers who can reliably meet their commitments without the risk of financial instability. Effective communication is vital for smooth coordination. Sharing demand forecasts, production schedules, and delivery timelines helps all parties stay aligned and proactively manage potential bottlenecks.[3] Supplier relationships should also include contingency planning for disruptions, such as geopolitical issues, natural disasters, or sudden market changes. Long-term partnerships based on mutual trust and shared goals foster collaboration and innovation, leading to improved efficiency and cost savings over time.[1] Regular performance evaluations based on metrics like delivery accuracy, product quality, and responsiveness help identify areas for continuous improvement. This collaborative approach enhances supplier performance and strengthens the overall supply chain, ensuring that laboratories can depend on their partners in both routine and crisis situations.[1]

3.3. Logistics and Transportation Optimization

Choosing logistics providers with robust networks and specialized capabilities is crucial, especially for handling temperature-sensitive and fragile materials.[1] Planning optimal transport routes and schedules reduces costs and transit times, aligning logistics with laboratory needs.[1] Real-time tracking technology provides visibility over shipments, allowing immediate action for potential delays. Emergency response plans developed with logistics partners address issues like lost or damaged shipments, ensuring minimal disruption and maintaining laboratory operations.[1][3] Efficient logistics ensure cost-effective, responsive deliveries that support consistent lab functioning.

3.4. Process Standardization and Continuous Improvement

Standardizing procedures is essential for ensuring consistency and reducing errors in laboratory operations. By implementing uniform protocols for procurement, inspection, and inventory management, labs can improve workflow reliability and reduce variability.[1] This also streamlines communication, minimizes mistakes, and ensures that materials meet quality standards.[2] Continuous improvement is equally important. Regular audits and evaluations help identify inefficiencies and optimize processes, ensuring that laboratories remain adaptable to changes like business growth or external disruptions.[3] A culture of continuous improvement encourages staff input, fostering innovation and efficiency. By adopting these practices, laboratories can improve resource management, boost productivity, and enhance operational resilience.

4. Conclusion

Effective laboratory supply chain management encompasses inventory control, supplier collaboration, logistics coordination, and ongoing process refinement. Adopting these strategies ensures reliable material supplies, boosts efficiency, minimizes costs, and strengthens support for both healthcare and research initiatives. Continuous optimization in this domain keeps laboratories resilient and ready to meet their essential mission.

References:

1. Alsalameh, S. A., & Ababeneh, M. F. (2018). Management of supply chain in clinical laboratories. International Journal of Scientific and Research Publications, 8(12), 565-570. https://doi.org/10.29322/IJSRP.8.12.2018.p8471

2. LabCompare. (2023). Streamlining the Laboratory Supply Chain. Retrieved from https://www.labcompare.com/10-Featured-Articles/607750-Streamlining-the-Laboratory-Supply-Chain/

3. Okeagu, C. N., Reed, D. S., Sun, L., Colontonio, M. M., Rezayev, A., Ghaffar, Y. A., Kaye, R. J., Liu, H., Cornett, E. M., Fox, C. J., Urman, R. D., & Kaye, A. D. (2021). Principles of supply chain management in the time of crisis. Best Practice & Research Clinical Anaesthesiology, 35, 369-376. https://doi.org/10.1016/j.bpa.2020.11.007

The first developed technology platform with various application scenarios, including infectious disease, fertility, DOA, etc.

The first developed technology platform with various application scenarios, including infectious disease, fertility, DOA, etc. 50+ kinds of reagents and five high-performance devices, focusing on detecting cardiovascular disease, inflammation, kidney injury, sex hormones, thyroid function, diabetes, tumor, and others.

50+ kinds of reagents and five high-performance devices, focusing on detecting cardiovascular disease, inflammation, kidney injury, sex hormones, thyroid function, diabetes, tumor, and others. Single-dose Chemiluminescense Immunoassay Platform

Single-dose Chemiluminescense Immunoassay Platform Wondfo optical blood coagulation analyzer is the first one in the world that can test PT, APTT, TT, FIB, and ACT simultaneously.

Wondfo optical blood coagulation analyzer is the first one in the world that can test PT, APTT, TT, FIB, and ACT simultaneously. Our Blood Gas Analyzer BGA-102 can produce the result in 30s. Its advantages of portability, easy operation, durability, and high performance make it ideal for clinics, laboratories, and hospitals.

Our Blood Gas Analyzer BGA-102 can produce the result in 30s. Its advantages of portability, easy operation, durability, and high performance make it ideal for clinics, laboratories, and hospitals. Ready-to-use lyophilized RT-PCR Reagent;

Ready-to-use lyophilized RT-PCR Reagent; Wondfo PA-3600 IHC Staining System

Wondfo PA-3600 IHC Staining System The Wondfo Truth-H80E HPLC Hemoglobin Analyzer is a high-performance diagnostic device designed for rapid and precise measurement of glycosylated hemoglobin (HbA1c)—the gold standard for diabetes diagnosis.It support the standard mode and variant mode and provide the result within 60-90seconds.

The Wondfo Truth-H80E HPLC Hemoglobin Analyzer is a high-performance diagnostic device designed for rapid and precise measurement of glycosylated hemoglobin (HbA1c)—the gold standard for diabetes diagnosis.It support the standard mode and variant mode and provide the result within 60-90seconds. This year, the summit will place a special focus on collaboration across different fields to explore the application of POCT and optimize clinical pathways. In the meantime, drive innovation by adoption of new technologies and biomarkers.

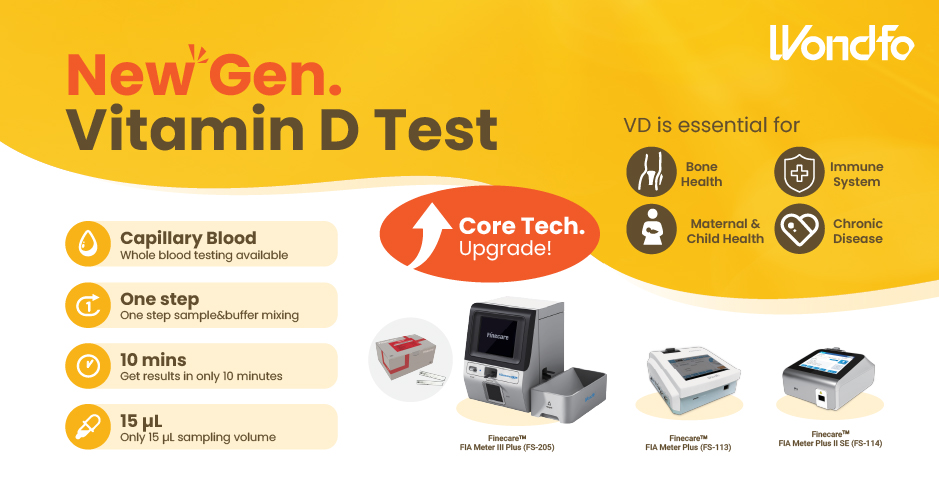

This year, the summit will place a special focus on collaboration across different fields to explore the application of POCT and optimize clinical pathways. In the meantime, drive innovation by adoption of new technologies and biomarkers. Finecare™ Vitamin D, from complexity to simplicity

Finecare™ Vitamin D, from complexity to simplicity Building A World Free from Antibitoic Overuse

Building A World Free from Antibitoic Overuse Advanced rapid diagnostic test with WHO prequalification for infectious disease

Advanced rapid diagnostic test with WHO prequalification for infectious disease The Future Intelligent Medical Assistant to Healthcare

The Future Intelligent Medical Assistant to Healthcare Fight against the pandemic through continuous innovation

Fight against the pandemic through continuous innovation